Photo: John and Suzanne’s Mom.

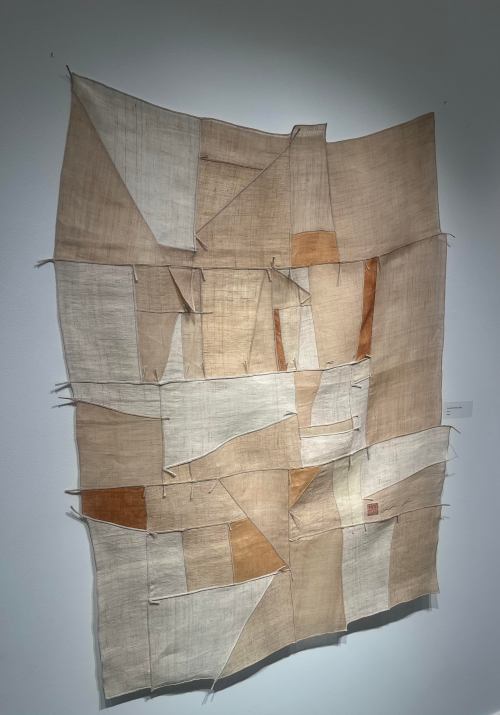

Chunghie Lee‘s bojagi style “No-Name Women Paper DuRuMaGill”: photo images silk-screen-printed on Korean mulberry paper dyed with ground oriental ink stick. At Lexington Arts in Massachusetts.

My friend Ann, the textile artist, put me on to a new/ancient type of quilting and fabric art. It’s from Korea and it’s called bojagi.

According to the websit for Beyond Above Publications, “Bojagi (Bo-Jah-ki), or wrapping cloth, is the ancient Korean folk tradition of making pieced textiles for both everyday and ceremonial use. Originally made by anonymous housewives to fulfill a practical need along with an artistic impulse, Bojagi and its techniques have recently gained attention outside of Korea due to the increasing interest in the value of handmade items, as well the use of recycled materials and the politics of sustainability in textiles and contemporary art.”

I would never know about this type of thing, but Ann is on every email list imaginable for textile art in Greater Boston and beyond. So one day I headed over to Lexington Arts and Crafts to see contemporary bojagi by artist Chunghie Lee.

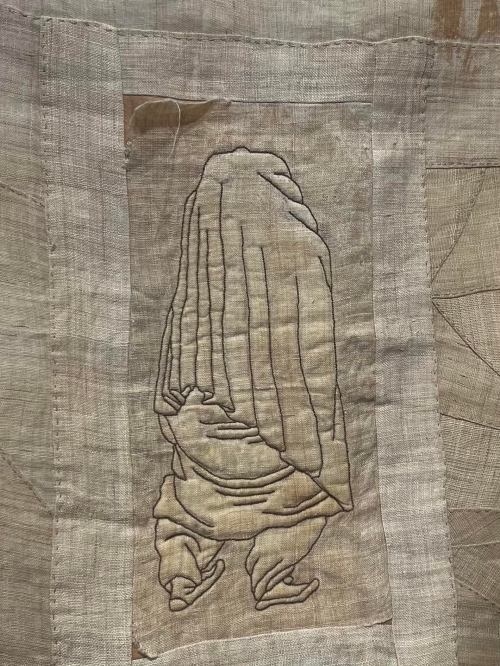

Apart from appreciating Lee’s skillful needlework, I was struck by her use of sustainable materials: previously used fabrics, mulberry paper, and ground-up ink sticks for red and black dyes. Especially moving was her focus on “no-name women,” the anonymous people behind this technique to make scraps of cloth go far. Women unknown and unappreciated.

You have to look closely to see them. Lee brings them into her work with silk screens of old-time photos, barely visible. Which is why for this piece I am showing you only a close-up.

Close-up of silk bojagi “no-name women” piecework by Chunghie Lee.

Here is more detail from the publishing company Lee founded with Jiyoung Chung, a visual artist inspired by the Joomchi papermaking tradition.

“From traditional women’s work to contemporary sustainable textiles, bojagi works include delicately pieced and hand-stitched traditional bojagi, reinterpreted bojagi, wearable pieces, installations, and wall hangings.

This uniquely Korean art form made by anonymous ancestors has evolved from functional works into a contemporary art form that is embraced worldwide.

“Since the late 14th century, every household, from the royal palace to the thatched-roof hut in a mountain village, has found these wrapping cloths indispensable. The tradition of making and using bojagi was established during the Josun Dynasty (1392 – 1910), when women were restricted from leaving their households. To spend the long, tedious hours of the day, girls were taught to sew at age ten, and needlework became a big part of their lives as they moved into adulthood. This folk art tradition was the only escape from the sequestered lifestyle of Korean women, and provided them with an artistic outlet for creative expression.”

Chunghie Lee adds, “I see this patchwork as a metaphor for human life. We may feel ourselves to be as random pieces of fabric, alone and without meaning, but God’s hand places us together in a beautiful composition, which has great harmony and meaning. As artists of all nationalities, generations and heritages, we discover we are all alike, and have been saving and making beautiful things with discarded fabric and other materials. In the eyes of artists, fabric scraps can be transformed and repurposed to fulfill the design and vision of the creator.”

More on bojagi at the website for publishing company Beyond Above, here. Follow Lee on Facebook, here.

Below, Chunghie Lee’s contemporary version of Korean piecework, followed by her careful stitching for “No-name Woman with Head Covering.”